"

Creating infinite design classics and making excellent Tangwei moulds

And make "Advanced, precise and cutting edge" moulds to meet the different needs of domestic and foreign markets.

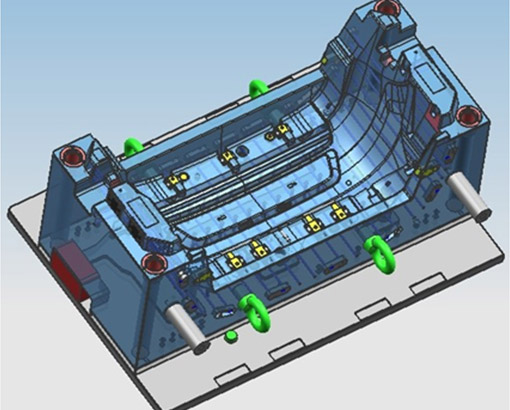

Design and development

Our Company is equipped with a series of advanced design software, mainly CATIA, UG, AUTOCAD, PowerMill, CAM and CAE. In the aspect of runner design, we use MOLDFLOW software to optimize and analyze, to eliminate all kinds of possible design problems in the development stage, which greatly improves the success rate of mould test.

Project management

Quality system

The Company follows ISO9001 Quality Management System, insisting on striving for perfection to win by quality, and making every detail carefully to give every mould a soul. At the beginning of each project, we analyze the key links and precautions of products in advance and make strict quality control arrangements. In the process of mould making, all working procedures will go through self-inspection, special inspection, spot check by professionals and verification by mould test to ensure that the processing is completed in one time and the mould quality meets customer standards.

01

Initial review, review and final review of mould design

02

Mould steel certification, hardness testing and standard parts testing

03

Regularly providing mould progress report to customers

04

Mould confirmation before each mould test

05

Test report and sample dimension inspection report

06

Final inspection and acceptance before shipment

Mold standard parts

Mould Rack:

DME, HASCO, LKM

Hot Runner:

HASCO, YUDO, Synventive 。

Hydraulic Cylinder:

PARKER, , HKS, STAUBLI

Standard Parts:

DME, HASCO, PUNCH, DAIDO, LKM

Steel:

2738,2311,718H,P20,S136,SKD61,NAK80,S50C等

Mould steel treatment:

1. Quenching pretreatment

2. Nitriding treatment of mould surface

Mold standard parts

一、Medium and small moulds

1. Cleaning the mould surface and coating it with antirust agent

2. Packaging moulds with film

3. Packing with reinforced wooden box

Contact us

Add:Huangyan Xicheng Mould City, Taizhou City, Zhejiang Province

E-mail:info@twmould.com / cjc@twmould.com